MATLAB and Simulink for Battery Systems

Design battery packs and develop battery management systems

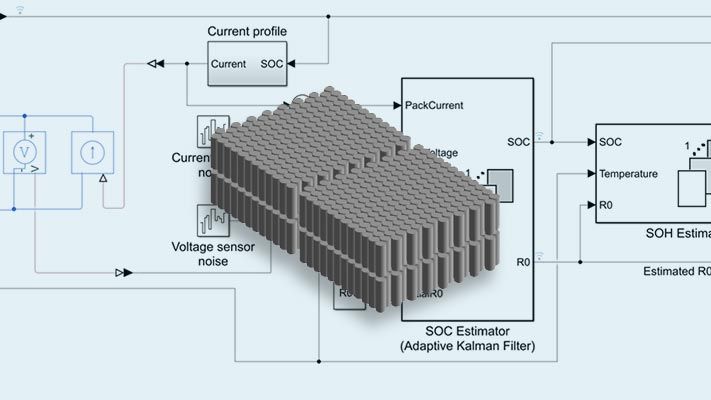

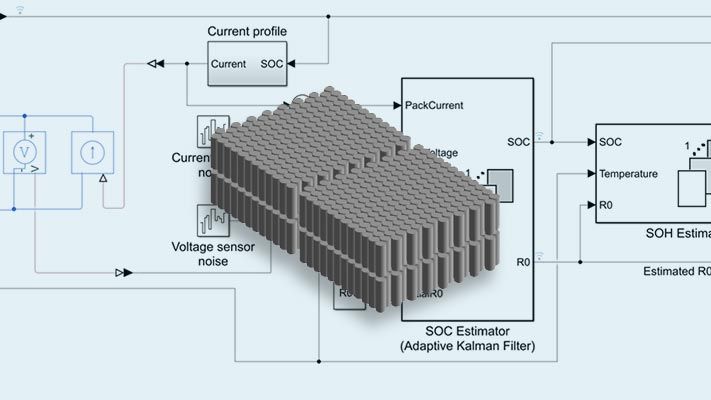

Simulink® and Simscape Battery™ provide a design environment so you can model battery cells, design different battery pack architectures, and evaluate thermal and electrical responses of battery packs across normal and fault conditions.

“Assessing battery pack performance using hardware prototypes can be both slow and costly, so we rely on simulation to ensure that we minimize hardware testing. Modeling and simulation with MATLAB, Simulink, and Simscape is faster, safer, and less costly than building physical prototypes.”

Cecilia Wang, Romeo Power

Use Simulink and Simscape™ to develop algorithms that ensure desired performance, safe operation, and acceptable lifespan under diverse operating and environmental conditions. With system-level simulation, verify functional aspects of the BMS design on behavioral models of battery, electrical circuitry, environmental conditions, and loads. Gain insight into the dynamic behavior of the battery pack and explore the effectiveness of BMS algorithms to:

“bat365 tools enabled us to develop key battery management technology using our own expertise, in an environment that facilitated early and continuous verification of our design.”

Dr. Xiaokang Liu, Dongfeng Electric Vehicle

Videos

Generate C/C++ and HDL code from Simulink and Simscape models for rapid prototyping (RP) or hardware-in-the-loop (HIL) testing to validate the BMS algorithms using real-time simulation. Emulate the BMS controller so that you can validate algorithms before generating and implementing code on a microcontroller or FPGA. Test a BMS controller before using hardware prototypes by conducting HIL testing to simulate the balance of the battery system.

“Speedgoat together with bat365 products offer us a very efficient workflow to design, test and validate algorithms for our battery management systems ...”

Marc Lucea, Leclanché SA

Learn More

Generate readable, compact, and efficient C/C++ and HDL code from battery system algorithms ready for implementation on production microcontrollers, FPGAs, and ASICs.

“We generated AUTOSAR-compliant C code from our controller models using Embedded Coder and the Embedded Coder Support Package for AUTOSAR Standard.”

Duck Young Kim, Won Tae Joe, and Hojin Lee, LG Chem