Induction Motor Speed Control

Develop and deploy induction motor speed control algorithms using Simulink

Develop and deploy induction motor speed control algorithms using Simulink

Design and implement motor control algorithms

Induction motor speed control is a process of manipulating currents in an induction motor to regulate speed. While often used in fixed frequency applications, induction motors are popular for variable frequency applications such as industrial drives and electric vehicles. For variable frequency operation, an inverter modulates current to the stator windings.

Slip and resulting torque for an induction motor

Legend:

Yellow arrow – resulting torque

Magenta arrow – rotating stator magnetic field

Blue arrow – rotor speed

Induction motors operate by a coupling of magnetic fields in the stator and rotor. Currents in the stator produce a rotating magnetic field that induce currents and a lagging magnetic field in the rotor. The magnetic field interaction causes the rotor to spin at an angular speed less than the rotational speed of the stator field. This rotational lag, called slip, provides torque at the motor shaft. Increasing load on the motor will increase slip and motor torque output.

For a squirrel cage-type induction motor, speed control using field-oriented control (FOC) regulates Id and Iq such that the flux is proportional to Id and the torque is proportional to Iq. This approach increases the speed range and improves both dynamic and steady-state performance. Simulink® lets you use multi-rate simulation to design, tune, and verify FOC algorithms across the complete operating range of the motor before hardware testing.

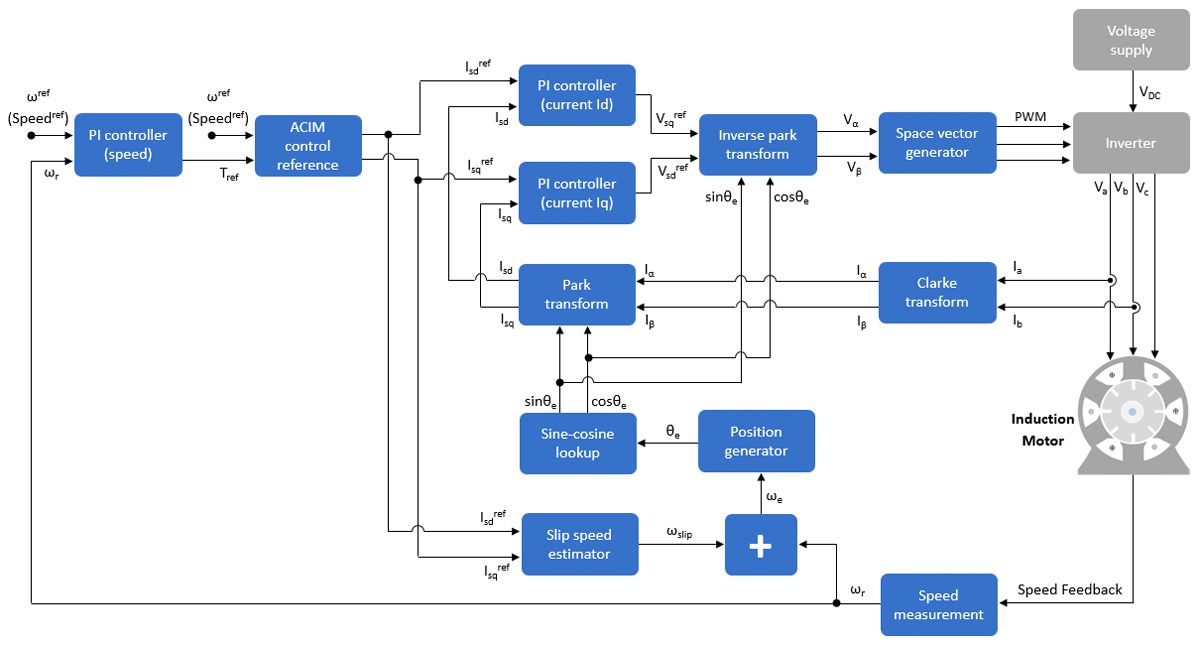

This Simulink diagram illustrates a typical FOC algorithm for speed control of a three-phase squirrel cage induction motor.

FOC algorithm for induction motor speed control.

The principle components of induction motor control strategies Include:

Simscape Electrical™ and Motor Control Blockset™ provide induction motor and field-oriented control examples of simulation model development for induction motor speed control. Simulating induction motor speed control with Simulink helps you reduce prototype testing and lets you verify the robustness of control algorithms to fault conditions that are not practical to test on hardware.

Using Simscape Electrical and Motor Control Blockset, motor control engineers develop induction motor speed control by:

Go from basic tasks to more advanced maneuvers by walking through interactive examples and tutorials.

The bat365 community for students, researchers, and engineers using Simulink to apply power electronics control to Electric Vehicles, Renewable Energy, Battery Systems, Power Conversion, and Motor Control.

Understanding BLDC Motor Control Algorithms

Read ebook